Fabrication Capabilities

Our sheet metal production facility can produce millions pounds of sheet metal a year, and our pipe fabrication facility can weld any type and size of pipe to meet any set of specifications.

Using our in-house resources, Cobb Mechanical manufactures round, rectangular and spiral duct products with state-of-the-art, high-speed equipment to ensure consistent quality on any job, large or small.

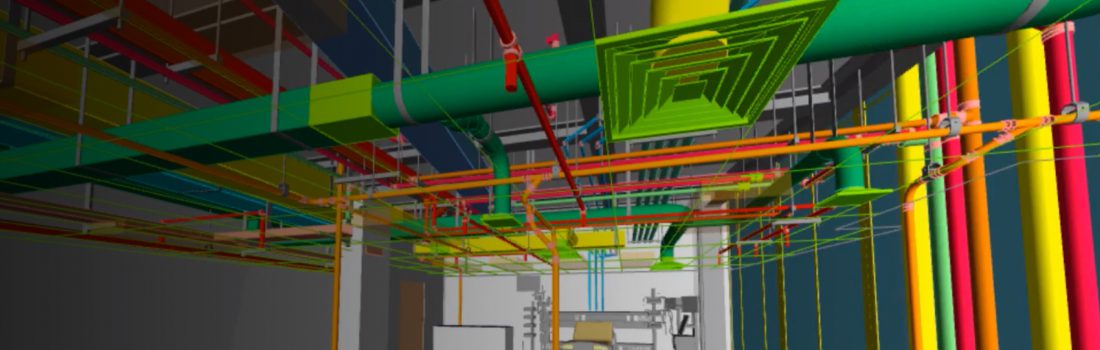

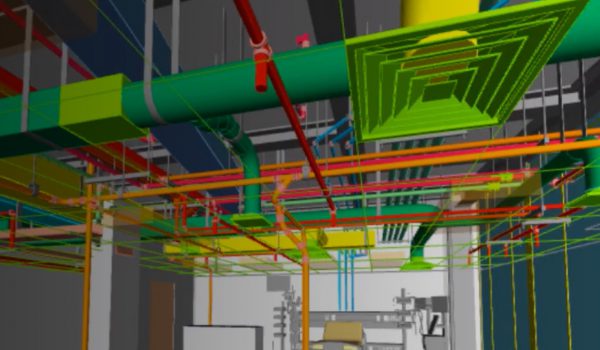

Cobb routinely pre-fabricates a variety of assemblies for shipment to project sites for quick, efficient installation. That includes yard piping for remote cooling towers and chillers; pump piping assemblies for machine rooms; control valve assemblies for heating and cooling coils on all types of HVAC equipment; plumbing wall “batteries” containing multiple toilets, urinals and lavatory piping; and main branch headers for central plant and machine room chilled water, steam and heating systems.

For specific projects where multiple trades are collaborating to gain the most out of pre-fabrication, Cobb can turn a portion of our shop into a job-specific manufacturing facility. This opens the pre-fabrication options to entire corridors and aboveceiling sections that include all piping, sheetmetal, conduit, cable tray, equipment and drywall that ship to the jobsite complete and only need to be installed into place. These assemblies can be drafted and coordinated in the modeling process and factory tested to ensure unmatched quality when compared to field-installed individual components.

Cobb has the industry’s most advanced coil line and an automated duct manufacturing machinery. Our dual de-coilers with a 10-coil capacity have the ability to process up to 16-gauge stainless steel with polished surfaces and up to 14-gauge mild steel capacity.

All of Cobb Mechanical’s in-house ductwork and fittings meet the SMACNA and ASHRAE specifications of 6-90/ASTM-653/ A924, and our shop standards have been verified by the SMACNA Testing and Research Institute. In addition, our round duct has been velocity tested by an independent party to ensure quality.

Cobb Mechanical also uses the latest welding equipment in its 17,000 square-foot piping fabrication plant, which includes a submerged arc machine that provides for extremely rapid welding of schedule 40 and heavier wall piping. All welding can be readily performed to radiographic quality levels when required by job specifications.