Safety

Cobb Mechanical’s EMR rating is one of the lowest in the mechanical industry.

Providing a safe working environment is the highest priority at Cobb Mechanical, and has been since the company was founded in 1969.

Our formal safety program, STOP for Safety, was implemented at Cobb Mechanical in 1991. It includes monthly safety audits at each jobsite and daily evaluations of changing jobsite conditions with immediate corrective action to unsafe conditions. Our successful approach to safety uses much more than just this program, utilizing both a top-down and bottom-up approach, with constant employee involvement. Safety starts at the time of employment with each prospective employee receiving HAZ COM training, a basic safety training review and a general review of OSHA’s specific safety requirements for confined spaces, fall protection, and PPE. When our employees get to the field their safety training is extended to cover specific job/activity hazard analysis. We also have a daily “job box” meeting where the work plan of the day is discussed along with GC safety bulletins. Each week, we also have a designated full-crew safety meeting where a topic of safety is reviewed.

Employee training is documented and updated regularly. We rely on constant supervision to monitor, review and improve our program. Currently over 95 percent of our superintendents have OSHA 30-hour certifications and many of our foreman also have either 30-hour or 10-hour certifications.

One advantage we have in safety is we have taken the steps to be certified trainers and train competent persons. Our safety director, Bobby Robbins, is dedicated to safety, not part time, full time. He is an OSHA 30 and OSHA 10 instructor and ASSE member. We have a second safety manager that is also an OSHA 500 qualified instructor for 10 hour and 30 hour instruction.

Cobb Mechanical is also a Registered CPR/1st Aid Training Center. Cobb Mechanical has made a commitment to safety in both personnel and resources. We don’t just believe in safety, we work it.

Safety has, and always will, come first at Cobb Mechanical.

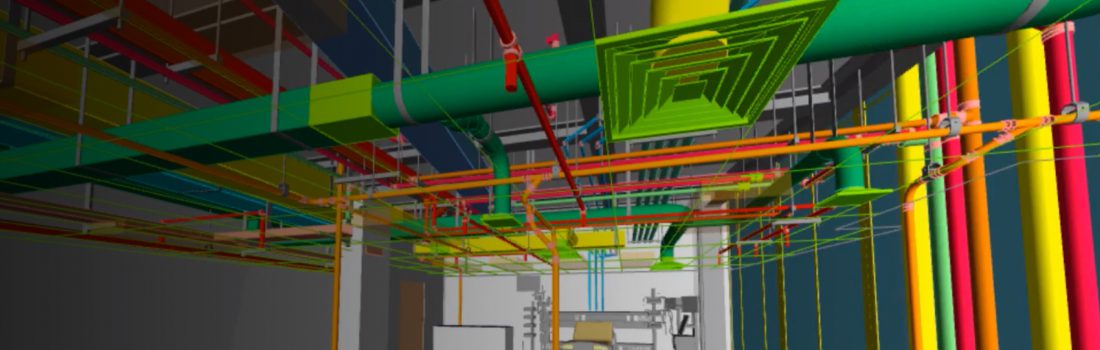

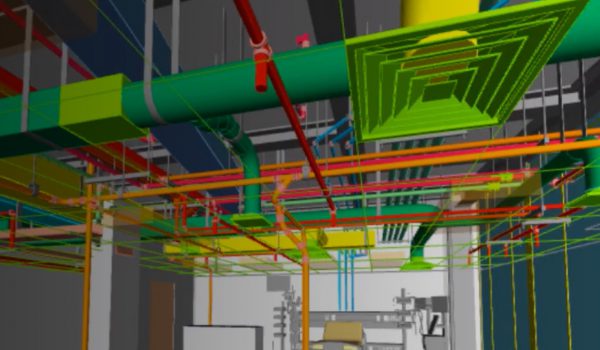

Quality Control, Quality Assurance

We have a Quality Control Operations Manager and a Quality Control Officer in the field dedicated to maintaining the highest caliber of installation in the trades. We also incorporate quality assurance procedures in our sheetmetal fab shop and pipe fab shop. Our quality control process is a start to finish system that starts with the contract drawings and specifications and follows the submittal process, receiving, material handling and field installation. Quality control personnel work independently from site management and are fully empowered to direct quality-related changes. During fabrication there is a complete procedural checklist performed as work is being done and prior to shipment. In the field the process includes active participation with the A/E team as necessary, and follows up through testing and inspections.

Every installation is complete with owner training and maintenance instruction. Our quality assurance is a guarantee you can believe in and trust.