Austin-Bergstrom International Airport

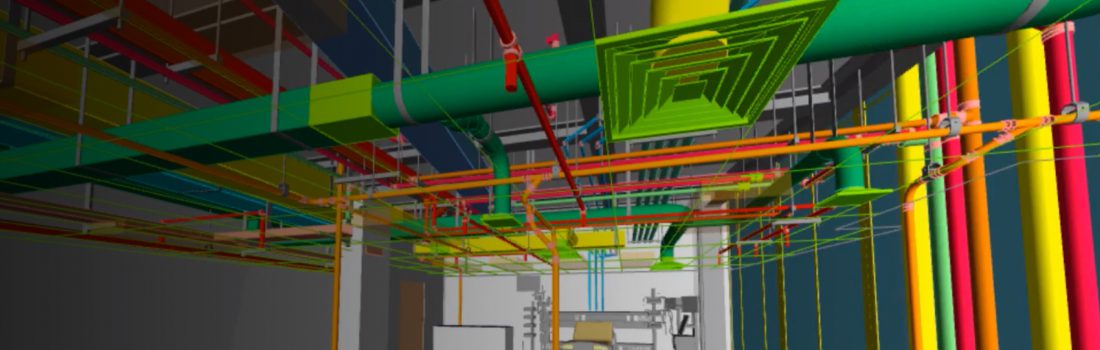

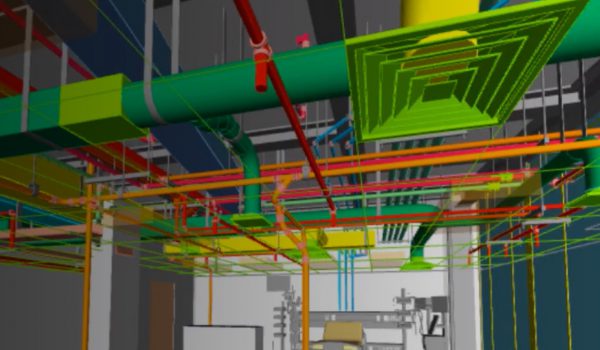

Austin’s airport, originally an 18-gate terminal facility with a footprint of 500,000 square feet, was expanded during construction to accommodate an additional six gates due to the amazing growth experienced in the Austin area.

The project was completed within the originally specified timeline, and stands as one of the most state-of-the-art airports in the country. The project makes extensive use of activated charcoal absorption filters to remove the jet fuel fumes from the ventilation air and used flexible grooved couplings to curve the main HVAC distribution piping to the architectural arc of the concourse level.

General Contractor: Morganti Group Inc.

Mechanical Contract Value: $14,406,096

Date Completed: 1999

William P. Hobby Airport

The $77 million facility renovation at William P. Hobby Airport added a new 374,000 square-foot, 20-gate central concourse for Southwest Airlines, and was a combination of new construction and retrofitting of an existing central chiller plant deep within the baggage service area of the existing airport.

Cobb Mechanical was responsible for removing all the chiller room equipment and piping from the existing central plant and then installing new chillers and piping, as well as the HVAC and plumbing services serving the new central concourse. To achieve this scope of work without disabling the existing HVAC comfort delivery systems, Cobb utilized a unique approach of using stand alone temporary water chillers and self contained DX air systems to keep the airport functioning and comfortable while all the chiller plant equipment was demolished and replaced/refurbished.

General Contractor: Morganti Group Inc.

Mechanical Contract Value: $7,639,880

Date Completed: 2005

George Bush Intercontinental Airport Central Plant

The upgrade of the central plant in Houston’s major airport was a multi-phase renovation/addition to the existing central plant in one of the largest airports in the country.

The new construction plus the existing facility was 25,000 square feet of equipment and piping. The project made use of high temperature/high pressure heating water for heating and cooling the entire expanded airport campus, which included new terminals D, E and the new customs inspection center.

General Contractor: Morganti Group Inc.

Mechanical Contract Value: $5,922,828

Date Completed: 2005